Introduction to Mechanical Watch Movements

Mechanical watch movement serves as the heart of a watch, powering its functions and ensuring accurate timekeeping. Unlike electronic watches, which rely on batteries, mechanical movements harness energy from the winding of a mainspring. This coiled spring stores energy and releases it through a series of gears and springs. These components drive the watch’s hands to move across the face, displaying the time. Mechanical movements come in various forms, the most traditional being the manually wound movement.

This type requires the wearer to wind the crown regularly to keep the watch running. On the other hand, automatic, or self-winding, movements use the natural motion of the wearer’s wrist to wind the mainspring. This type offers convenience, as it eliminates the need for manual winding as long as the watch is worn regularly. Understanding mechanical watch movements provides a deeper appreciation for the craftsmanship and engineering that goes into creating these intricate devices. They are not just timekeepers; they are marvels of mechanical art.

Evolution of Mechanical Movements

The journey of mechanical watch movements has been marked by innovation and refinement. Over the centuries, watchmakers have perfected the art of timekeeping, leading to significant milestones that continue to impress.

The Birth of the Automatic Movement

The automatic movement is a key chapter in the evolution of watches. It first came into play in the late 18th century when Abraham-Louis Perrelet introduced a system that harnessed the motion of the wearer to wind the mainspring. This breakthrough paved the way for the development of self-winding watches, which made timekeeping more convenient. In 1923, John Harwood patented the first practical self-winding wristwatch setting the standard for future automatic watches. The beauty of these movements lies in their fusion of traditional craftsmanship with the practicality of modern innovations.

Advancements in Power Reserve

Following the innovation of the automatic movement, advancements in power reserve became a focus for watchmakers. The power reserve of a watch indicates how long it will run after being fully wound, with many contemporary mechanical watches offering between 40 to 50 hours of power reserve. Watch brands have continually pushed these limits, introducing movements with extended power reserves. Brands like Panerai offer 72 hours or more, while the Hublot MP05 La Ferrari boasts a record-breaking 50-day power reserve. The quest for longer power reserves reflects watchmakers’ commitment to convenience and reliability in mechanical watch design.

Quartz Movements Versus Mechanical Movements

Quartz and mechanical movements are the two main types of watch movements. Each has unique benefits and works differently.

Understanding Quartz Movements

A quartz movement uses a battery. This sends an electric charge through a quartz crystal, making it vibrate. These vibrations keep the watch hands moving accurately. Quartz movements are known for precision. They can be more accurate than mechanical ones, often deviating less than 15 seconds a month.

Advantages of Quartz Movements

- Accuracy: Quartz watches are highly accurate. They rarely lose or gain seconds over weeks or months.

- Low Maintenance: They need less care than mechanical watches. Usually, only battery changes are needed.

- Affordability: Making quartz movements costs less. This often makes the watches more affordable.

- Durability: Fewer moving parts mean fewer problems. Quartz movements can handle more wear and tear.

Understanding Mechanical Movements

Mechanical movements use a wound spring for power. No batteries are involved. Gears and springs release energy to move the hands. Mechanical watches showcase the art of watchmaking.

Advantages of Mechanical Movements

- Craftsmanship: They represent a tradition of intricate design and detail.

- Aesthetics: Many appreciate the visible moving parts and craftsmanship.

- No Battery Needed: Wearing or winding a mechanical watch keeps it running.

- Eco-Friendly: With no battery, they are a greener choice compared to quartz.

Choosing Between Quartz and Mechanical Movements

The choice comes down to preference. You may choose quartz for accuracy and ease. Or, you might prefer mechanical for its craftsmanship and legacy. Both types have their place in the world of watches, each admired for different reasons.

Seiko’s Spring Drive Movement Explained

Seiko’s Spring Drive movement represents a unique blend of mechanical and quartz technologies. Introduced in 1999, this movement is distinct in its method of operation, which differs significantly from traditional mechanical or quartz movements.

How Does Spring Drive Work?

At its core, the Spring Drive utilizes a mainspring, similar to traditional mechanical watches, which users can wind manually or which can wind automatically through the motion of the wrist. What sets it apart is the integration of an electronic regulator that uses a quartz crystal. This quartz crystal provides incredible accuracy.

The movement’s ‘glide wheel’ is central to its function. This wheel rotates rapidly, generating an electrical charge. This charge powers the quartz crystal, producing precise electrical impulses. These impulses control the speed of the glide wheel, thus ensuring exceptional timekeeping precision.

Benefits of the Spring Drive Movement

- Precision: The quartz crystal enhances accuracy, making the Spring Drive one of the most precise movements available.

- Smooth Movement: Unlike typical mechanical watches, the Spring Drive’s hands move in a smooth, sweeping motion rather than the usual tick-tock.

- Reliability: Combines the robust features of mechanical movements with the precision of quartz.

- Pioneering Technology: Represents a significant technological advancement in watchmaking.

Seiko’s innovative approach provides watch enthusiasts with a hybrid that offers the best of both worlds. This movement is most commonly found in Seiko and Grand Seiko watches, marking a hallmark of the brand’s pioneering spirit in watch engineering.

Solar Power: The Eco-Friendly Watch Movement

Transitioning from traditional mechanical watch movements, the solar-powered watch movement represents eco-friendliness in timekeeping. Solar movements operate on a simple yet innovative premise: exposure to light charges a battery, eliminating the need for frequent battery replacements. The key advantage here, apart from environmental friendliness, is the reduced maintenance and long-lasting power reserve.

Harnessing Light for Energy

Solar watch movements include small solar panels, often hidden under the dial, which convert light into electrical energy. This energy charges a rechargeable cell, providing a consistent power source for the watch’s operation. As a result, sun or artificial light keeps the timepiece functional.

Benefits of Solar Movements

- Eco-Friendly: Solar watches reduce battery waste, making them a greener choice.

- Low Maintenance: With solar energy, the need for battery replacements is minimal.

- Durable Power Reserve: Once fully charged, some solar watches can run for months without additional light exposure.

- Innovative Technology: The integration of renewable energy in watchmaking is a technological leap forward.

Recognized for their positive environmental impact and modern innovation, solar watch movements have been well-received in the watch industry. Brands like Citizen with their Eco-Drive technology showcase how traditional timekeeping can adapt to sustainability trends. This tech not only increases the functional lifespan of the watch but also aligns with contemporary eco-conscious values.

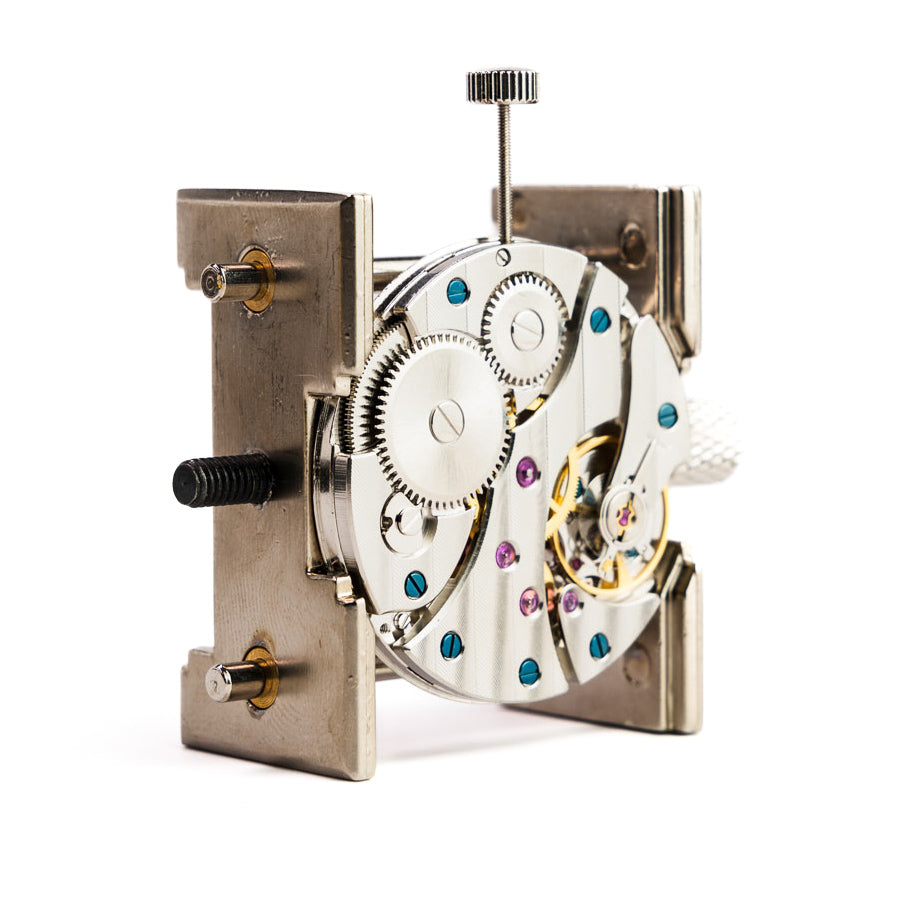

Anatomy of a Mechanical Watch Movement

To truly appreciate the intricacies of a mechanical watch, one must understand its anatomy. Each component works in harmony to track time.

The Main Components and Their Functions

Key components form the core of a mechanical watch movement, each with a crucial role:

- Mainplate: This is the base that supports all other parts. It’s typically a flat metal foundation.

- Mainspring: A coiled spring, this is the power source for the watch. Once wound, it slowly unwinds to drive the movement.

- Gear Train: A series of gears that transmit energy from the mainspring to the escapement.

- Escapement: This device controls the release of the watch’s power. It ensures the gears advance at a steady pace.

- Balance Wheel: Paired with the hairspring, this wheel oscillates to regulate timekeeping.

- Jewels: Synthetic rubies or sapphires reduce friction at high-stress points, improving accuracy and longevity.

- Rotor: In automatic movements, this weighted part winds the mainspring as the wearer moves.

Understanding these components shines light on the precision and craft behind mechanical watches.

The Aesthetics of Movement: Decoration and Skeletonization

The beauty of a mechanical watch movement lies not only in its function but also in its design. A well-crafted movement is not just a tool for timekeeping—it’s a work of art. Here, we delve into the aesthetics of movement, focusing on the art of decoration and the intriguing charm of skeletonization.

Movement Decoration

To add visual appeal, watchmakers often decorate their movements. Here are common types of decoration:

- C?tes de Genève: Parallel lines or waves on parts like the mainplate or bridges.

- Perlage: Circular graining, which looks like tiny overlapping circles.

- Anglage: Polished, beveled edges that create a shine on movement parts.

- Blue Screws: Screws heated to high temperatures to achieve a distinctive blue color.

- Engraved Rotors: Automatic movements may have rotors engraved with brand names or fancy designs.

These artistic touches do more than beautify; they often signify the watch’s quality and maker’s skill.

Skeletonization: A View to the Heart

Skeletonization strips away non-essential metal from the movement. This lets you see the intricate components at work. Here’s what it involves:

- Openworking: Removing extra material to showcase the movement’s mechanical beauty.

- Transparency: Watches with skeletonized movements often have clear dials or backs.

- Craftsmanship: It takes skilled artists to skeletonize a movement without compromising its function.

Skeletonized watches are not only fascinating to watch enthusiasts but also appeal to those who admire fine craftsmanship.

Understanding Chronometer Certifications

Chronometer certifications are benchmarks for precision in watch movements. They assure that a watch meets specific accuracy standards. To be labeled as a chronometer, a movement must pass tests from authorized organizations. Here’s a look into these certifications and what they entail:

- COSC Certification: The most recognized standard comes from the Swiss Official Chronometer Testing Institute (COSC). Watches must endure rigorous testing over 15 days in various positions and temperatures. To pass, they should maintain an average daily rate of -4/+6 seconds.

- Other Notable Certificates: Some brands go beyond COSC standards. Omega’s ‘Master Chronometer’, Patek Philippe’s ‘Patek Philippe Seal’, and Rolex’s ‘Superlative Chronometer’ all represent higher levels of accuracy.

- Impact on Watch Value: Watches with chronometer certifications often hold higher value. They signify superior performance and reliability. Collectors and enthusiasts seek these for their collection.

Obtaining a chronometer certification isn’t easy. It’s a sign of quality and excellence in mechanical watch movement manufacturing. When choosing a watch, a chronometer-certified model represents a smart choice for precision and craftsmanship.

The Journey from ‘bauche to Manufacture: Movement Production

The production of a mechanical watch movement is a complex process that starts with an ébauche and culminates in a finished manufacture movement. Understanding this journey is key to appreciating the value and craftsmanship of a timepiece.

An ébauche is essentially the skeleton of a watch movement, composed of the basic components but lacking some critical parts like the escapement and mainspring. It’s like the framework onto which the remaining pieces are added. Watchmakers take these incomplete kits and skillfully integrate the missing elements, crafting a movement that’s ready for precision timekeeping.

Moving from an ébauche to a manufacture movement involves meticulous design and production. ‘Manufacture’ refers to movements created entirely in-house by a watch brand. This means every tiny component, from gears to screws, is made and assembled under one roof. Such a process demands a high level of expertise and quality control, ensuring the resulting movement lives up to the stringent standards expected in luxury watchmaking.

Some of the most renowned names in watchmaking, like Rolex, Patek Philippe, and A. Lange & S?hne, pride themselves on producing manufacture movements. They represent the pinnacle of watch movement design, embodying the brand’s legacy and dedication to the art of horology.

While not all watch brands can boast in-house production, many still provide high-quality movements by refining and customizing ébauches sourced from specialized suppliers. Brands like ETA and Sellita are famous for producing reliable ébauches and movement kits that numerous watchmakers across the industry use.

In summary, the process from ébauche to manufacture is an elaborate one that showcases the watch industry’s innovation and attention to detail. It’s a journey that underscores the prestige of a fully in-house movement and the craftsmanship behind every mechanical watch.

The Role of Rotor Types in Automatic Movements

Automatic movements rely on the movement of the wearer’s wrist to wind the mainspring. The rotor, a key component, plays a crucial role in this process. Here, we explore different types of rotors and how they influence the functionality of automatic watches.

Center-Mounted Rotors

The most common type of rotor found in automatic movements is the center-mounted rotor. This semicircular piece swings freely in a 360-degree motion as it converts arm motion into energy that winds the mainspring. Its design allows it to cover a large part of the movement, making it efficient in maintaining the power reserve.

Micro-Rotors

Micro-rotors offer a similar function but are smaller and integrated into the movement. This design helps in reducing the thickness of the watch, making it more comfortable for daily wear. Brands like Piaget and Patek Philippe are notable for their use of micro-rotors, especially in their ultra-thin watch models.

Peripheral Rotors

A less common but innovative type is the peripheral rotor. It encircles the edge of the movement, allowing an unobstructed view of the movement through the case back. This type not only enhances the aesthetic appeal but also maintains the efficiency of winding. Carl F. Bucherer is known for pioneering this type of rotor in its watches.

Each rotor type brings its own benefits and considerations. The choice of rotor type impacts both the performance and the design aesthetics of a watch. Watchmakers select rotor types based on the desired balance between functional efficiency and visual appeal.

The Pioneers and Innovators of Mechanical Movements

The history of mechanical watch movements is marked by pioneers and innovators. Their relentless pursuit of precision and functionality shaped the world of timekeeping as we know it today.

- Abraham-Louis Perrelet: Known as the father of the automatic movement, Perrelet created the first self-winding mechanism in 1777. This laid the foundation for modern automatic watches.

- John Harwood: Patented the first practical self-winding wristwatch in 1923. His design eliminated the need for manual winding, setting a new standard for watches.

- George Daniels: An eminent horologist who invented the coaxial escapement. This reduced the friction between moving parts, enhancing the accuracy and longevity of watches.

- Seiko: This Japanese company revolutionized watch movements with its introduction of the Seiko Spring Drive in 1999. This cutting-edge hybrid movement combined mechanical art with quartz precision.

- Citizen: Pioneered the Eco-Drive technology in 1976, which harnessed light to power watches. This innovation steered the industry towards sustainable, battery-less timekeeping.

These key figures and brands have made lasting contributions that continue to inspire and influence the design of mechanical watch movements. As watch enthusiasts, we owe much of our current appreciation for timepieces to these innovators and their groundbreaking work.